This guest post is written by our friend Brittany Wood Nickerson, a well-respected herbalist and health educator with a background in Western, Ayurvedic and Chinese herbal medicine. Her treatment and teaching approach emphasize personal empowerment, preventative home healthcare and whole body wellness. Brittany is the founder and primary instructor at Thyme Herbal in Western Massachusetts, where she teaches a three year Herbal Apprenticeship Program. She teaches women’s health at the University of Massachusetts and is the organizer of the Northampton/Amherst Herbal Meet-up group. Brittany is the author of The Everyday Living Series, The Herbal Homestead Journal and her newest work: Recipes From the Herbalist’s Kitchen, to be published by Storey in Spring 2017!

I first met my fiancé, Casey Steinberg, when buying salad greens at his Old Friends Farm stand at the Amherst Farmer’s Market. He was handsome, and his greens were really good! In the fall they had bountiful baskets of fresh ginger and turmeric – I had never seen anything like it! Casey and his business partner, Missy Bahret, pioneered growing ginger in northern climates in 2004. A few years later they began growing turmeric and now, almost a decade later, this practice has caught on. Today, Old Friends Farm gets regular inquiries about growing ginger from farmers in locations ranging from California to Vermont, and Costa Rica to Germany.

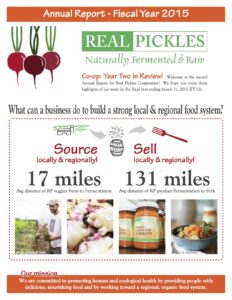

It is important to include medicinal herbs in our efforts to forge a vibrant local and regional food system. Culinary traditions are based on ancient wisdom. Cooking with herbs and spices makes food easier to digest and kills bacteria associated with food borne illnesses. You might put basil on your pasta or cumin in your curry because it tastes good, but these practices have been passed on by generations of cooks who seasoned food with herbs because it was practical, necessary and healthful.

The caraway seeds found in many traditional sauerkraut recipes are a perfect example. Cabbage can cause gas and bloating, but caraway seeds make the cabbage easier to digest and help reduce gas. Traditional spices, such as the black pepper and dill in pickles, help warm and balance the cold energy of cucumbers. Once you understand these principles you start to see them everywhere and you can make up your own traditions. Excellent examples from the Real Pickles’ collection include: Red Cabbage with thyme, winter savory and marjoram; Beets with rosemary and onion; Ginger Carrots; and their new, absolutely fabulous Turmeric Kraut!

Turmeric is a powerful medicinal herb, traditionally used in cooking and medicinal preparations. It is a mildly warming, aromatic, bitter digestive aid. It stimulates liver function and the release of bile, which helps with the digestion of fats and oils. It improves the breakdown and absorption of nutrients and relieves gas and bloating. Turmeric supports digestive metabolism, liver metabolism, and cellular metabolism, which aids in detoxification and helps to relieve inflammation.

Holistic health sees the health of each part of a system being integrally connected to the health of the whole. In the body, holistic health starts with good digestion. If digestion is compromised, all other systems become compromised. A well functioning digestive system allows us to absorb the most nutrients from our food and to expel waste effectively. Our digestive system is also closely tied to the nervous system. The enteric nervous system, which governs digestion, has almost as many neurons as the brain! It connects the digestive system to all other systems in the body. Aromatic culinary herbs help relax the GI tract and calm the nervous system, while at the same time relieving many digestive upsets.

Fermentation, like cooking with culinary herbs, makes food easier to digest. Fermented vegetables also contain beneficial bacteria, which have been shown to improve skin health, decrease allergies, and increase immunity (see Real Pickles’ health page for more info). Lactic acid, produced during the fermentation process, makes fermented foods taste sour – hence the name sauerkraut. As if everything we have learned so far isn’t enough, the sour flavor is also great for digestion! Sour tasting foods stimulate the secretion of acids and enzymes, as well as bile from the liver and gall bladder. The probiotics and sour flavor of kraut combined with the bitter, aromatic and mildly warming energy of turmeric are a perfect recipe for holistic wellness. The benefits complement one another, improve digestion and help to support whole system balance.

As organisms in a larger system, our holistic wellness is dependent on many interconnected systems: environmental, economic, social and cultural. Efforts to restore local and regional food systems and economies understand this kind of holism, recognizing that our food is only as healthy as the system from which it comes. Real Pickles’ commitment to producing healthy food and creating a sound regional food system is a role model for the planet. We need more businesses willing to think outside the box and be structurally creative – committing to policies that support workers, distributors, retailers, consumers and the environment in ways that foster health on all levels.

Years after we met, I was teaching Casey how to make sauerkraut in our home kitchen, and he said, “let’s add turmeric!” It was harvest season, and we had fresh turmeric coming out our ears! We were very excited to share our first batch with Real Pickles. Cabbage and turmeric have not traditionally been grown in the same climate, which is part of what makes this product so special and unique. Real Pickles and Old Friends Farm have created a special partnership which builds on each other’s innovations and shared mission to work toward a thriving local and regional food system. This is health as it should be – interconnected, responsible and delicious.